Posted

Watch the wheels in motion, check out our short process video below!

Watch the wheels in motion, check out our short process video below!

Here at Vektor, we like to get our heads in the game, before shouting about our skills we like to put ourselves to the test. We decided that it was time to polish our full colour screen printing process on white garments.

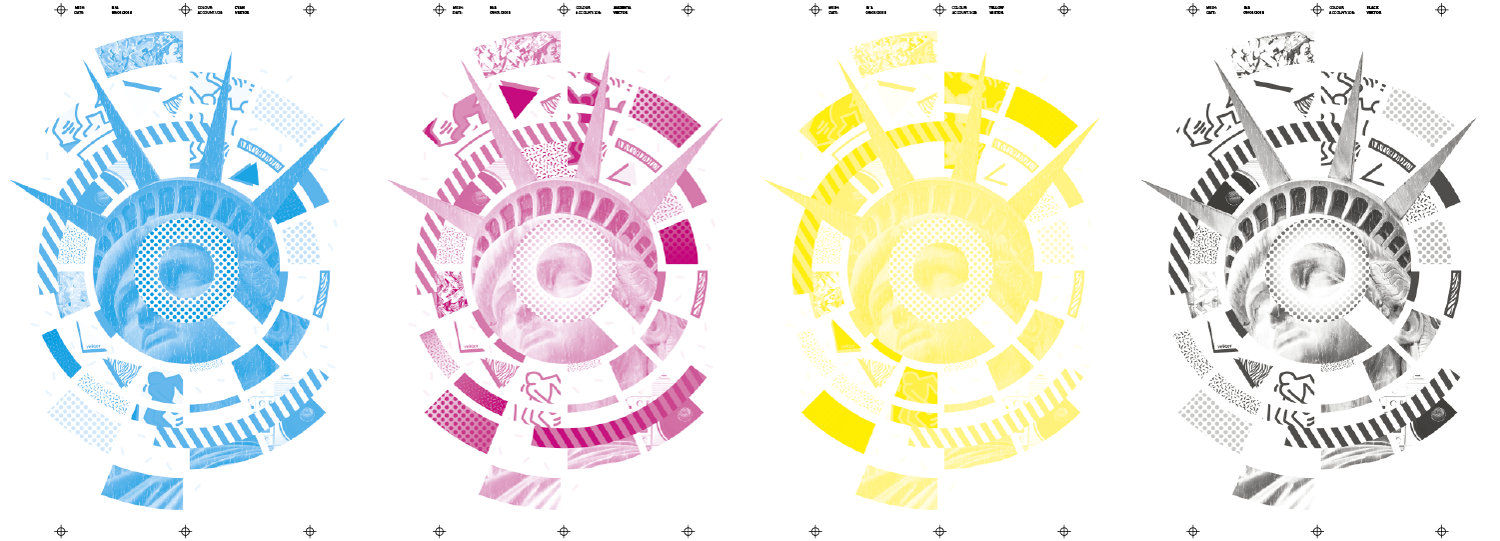

The first challenge was for our in-house graphics team to create an attractive t-shirt design with a New York theme using a CMYK pallet.

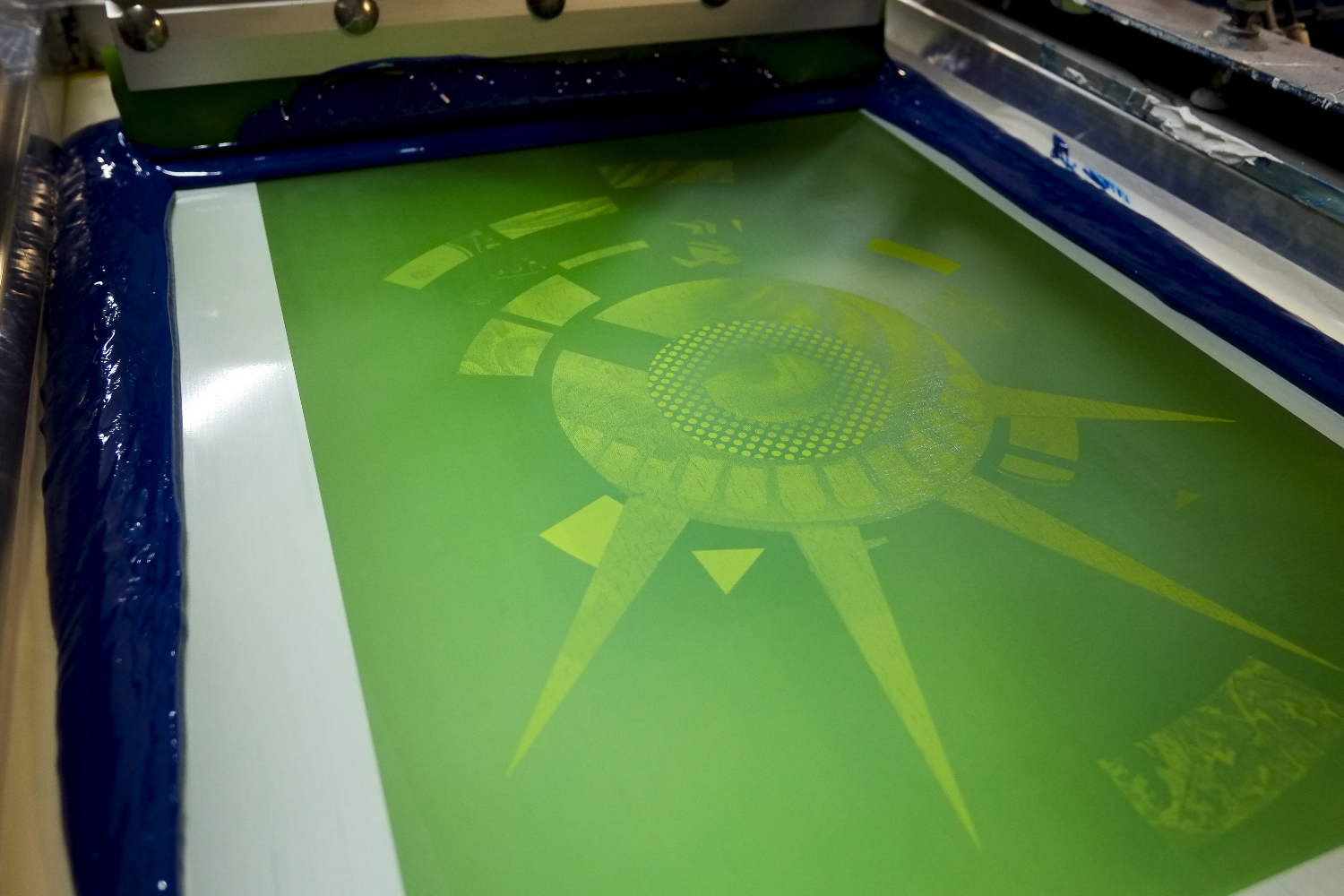

That achieved, led us on to see what we could do to ensure the best colour reproduction and after much testing, we opted for FM or stochastic screening for the colour separations. The advantage of this over the ‘normal’ halftone so frequently used is that a much finer dot is printed ensuring more detail is preserved and moire is completely eliminated.

Of course, you have to measure your results as the halftone dots tend to grow when printed leading to ‘dot gain’ which makes prints too dark. We used our transmission densitometer to take those crucial measurements on the films and a mesh tension meter to ensure the high tension required so that the printed result is faithful to the artwork files.

The inks are also adjusted so that they match the colour values used in the software separation process. These are checked using a spectrophotometer, a device that reads colours and gives information that can be compared to the target.

In short, the separations, film positives, screens and print sequence all contribute to achieving great results. When coupled with a skilled print team the results are really stunning prints at reasonable cost.

The final screen prints have been reviewed by a number of experienced buyers who have been uncertain as to whether they were printed digitally or by screen – music to our ears as it validates our efforts.

The old adage ‘If you can’t measure it, you can’t manage it’ is especially true when printing 4 colour process screen printing in textiles.

We’ve done the hard work, our process is standardised so that your orders look great first time, every time.

Colour Separated Films

FM Halftone Film Checking

Exposed & Washed Silk Screens

Screens Loaded & Registered

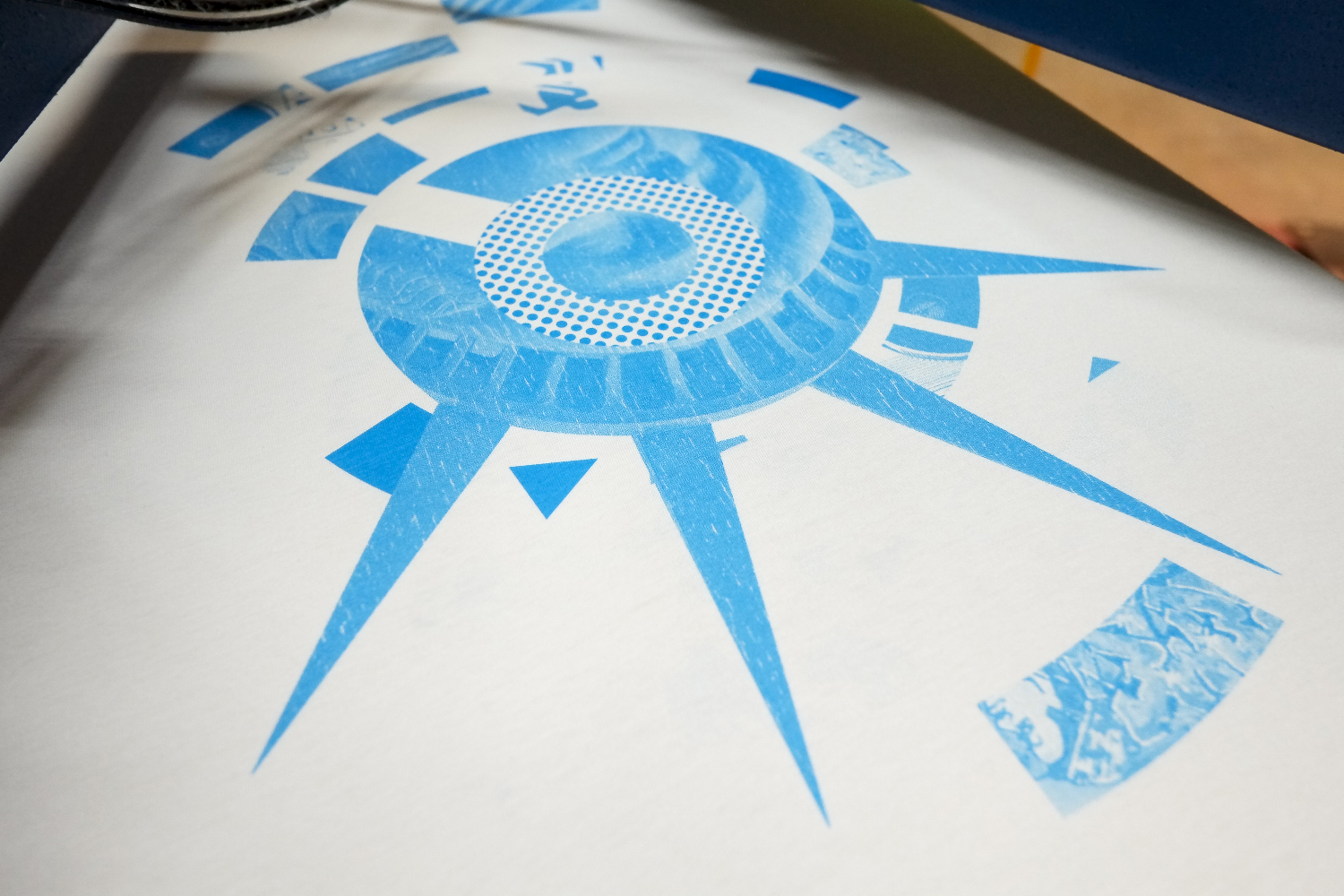

Screen C – Cyan Ink

Screen C – Cyan Ink

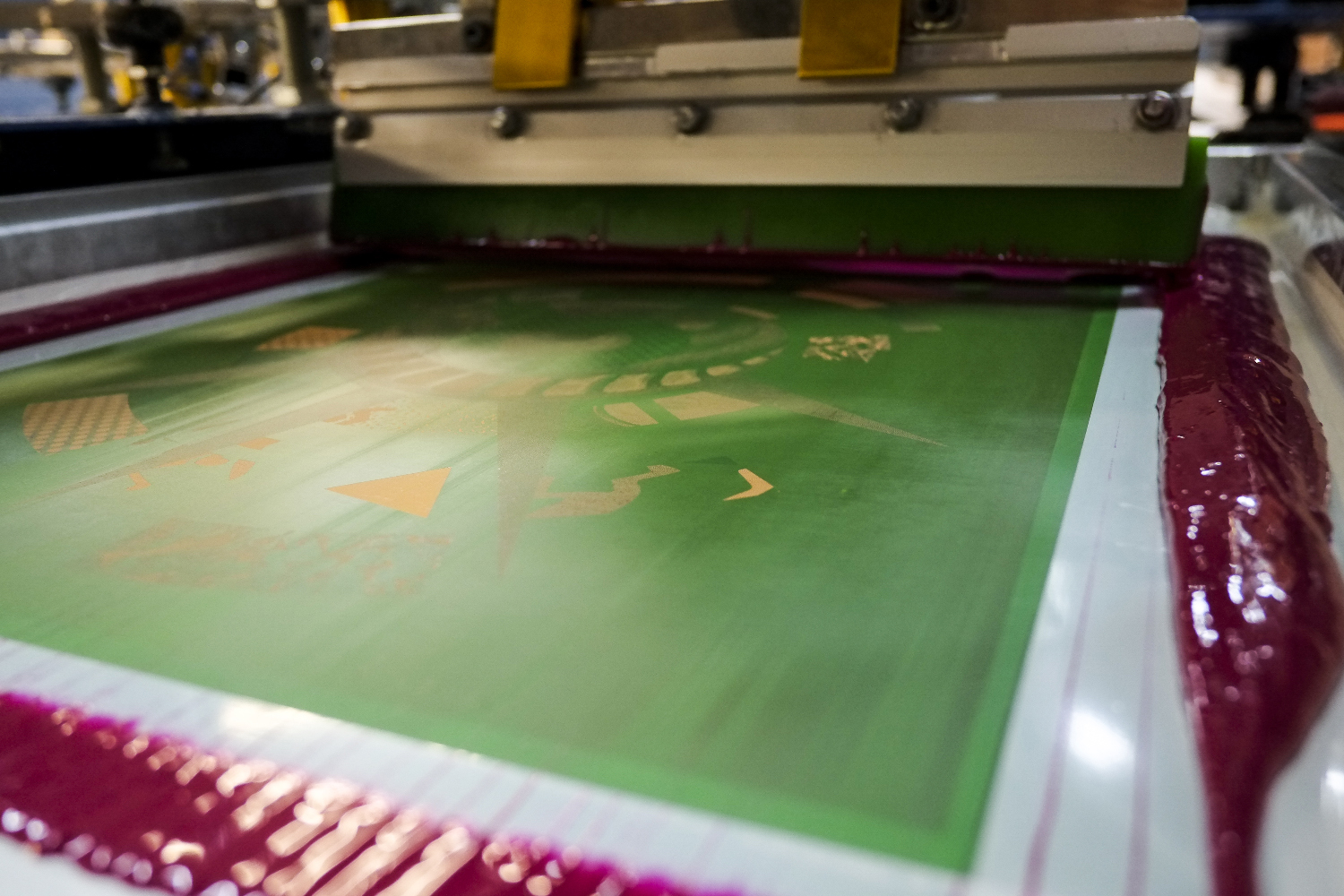

Screen M – Magenta Ink

Screen M – Magenta Ink

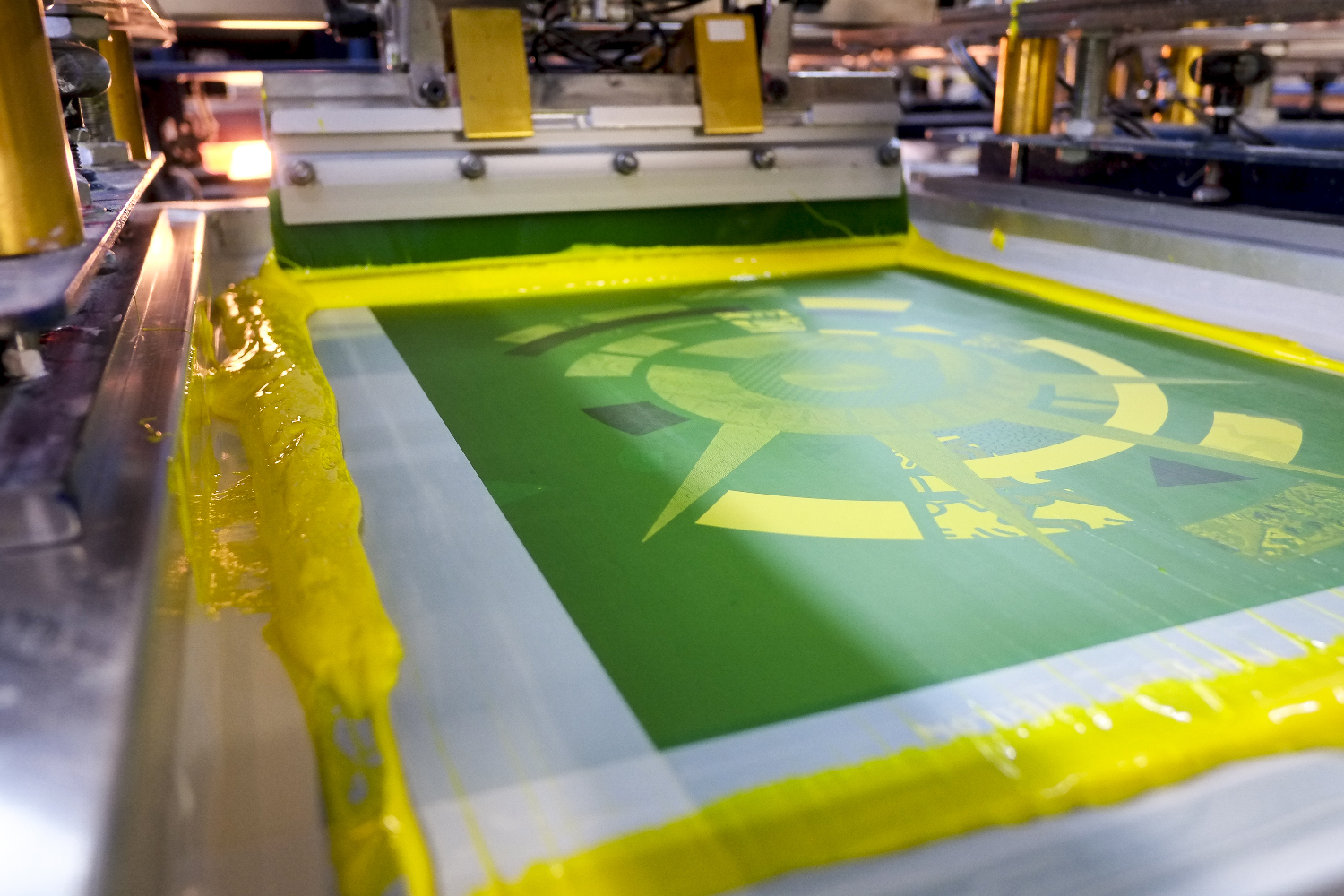

Screen K – Yellow Ink

Screen K – Yellow Ink

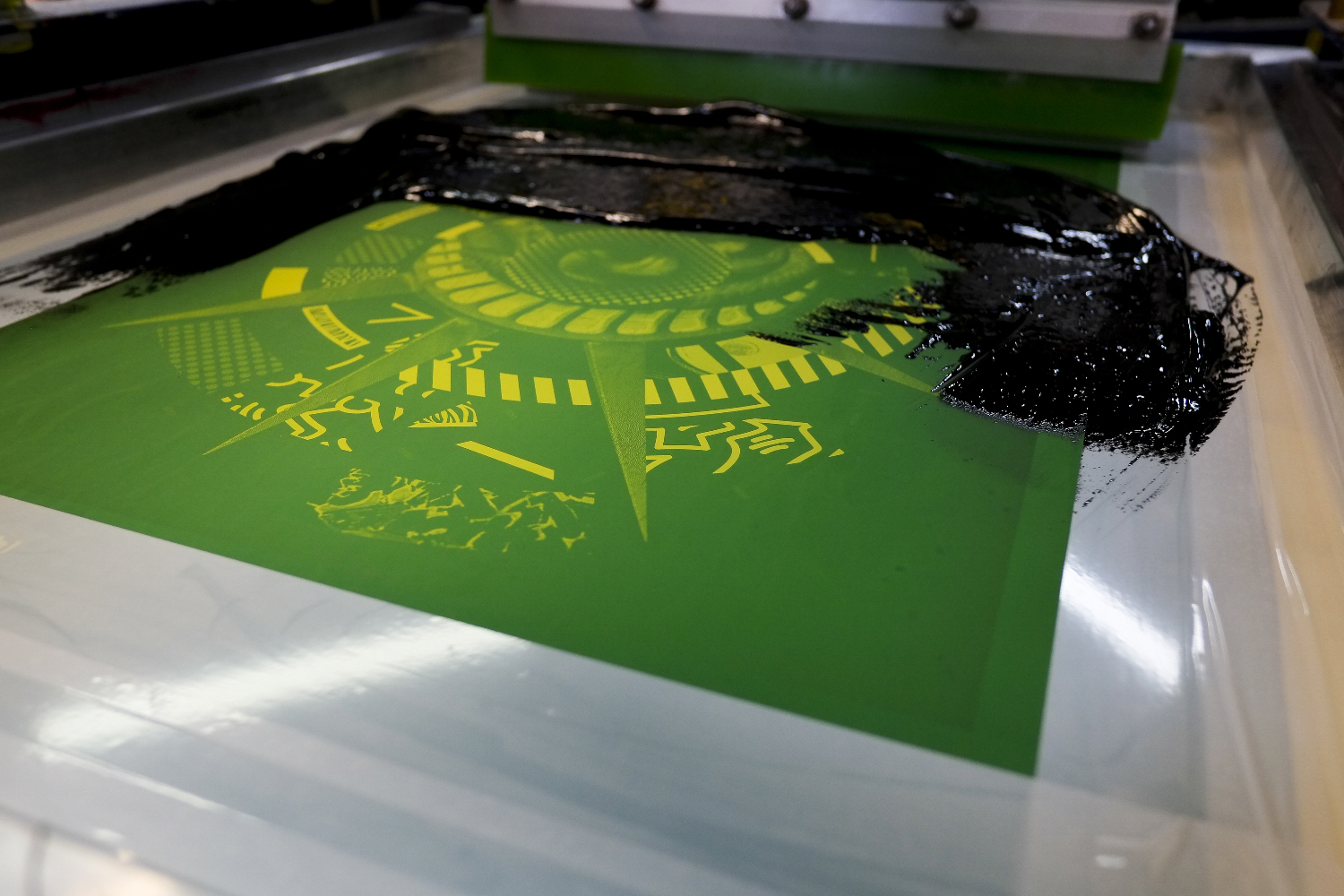

Screen K – Black Ink

Screen K – Black Ink

Completed CMYK Print

Completed CMYK Print

Completed CMYK Print

Ink Curing Process

True Light Colour Matching

Colour Gamut Reading & Dot Gain Check